SMC: Silpara Molecular Composites

A Reinforced Network for better Polymer-Filler Interaction

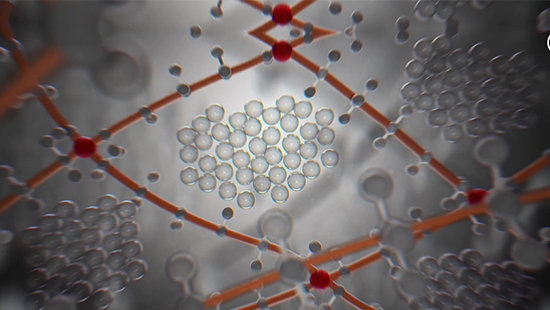

Common Natural Rubber Silica Network

Natural rubber and silica form weak bonds when mixed. These weak bonds, known as polymer-filler interactions, create molecular friction when the compound is flexed. Poor polymer-filler interaction thus leads to wasted energy through heat dissipation.

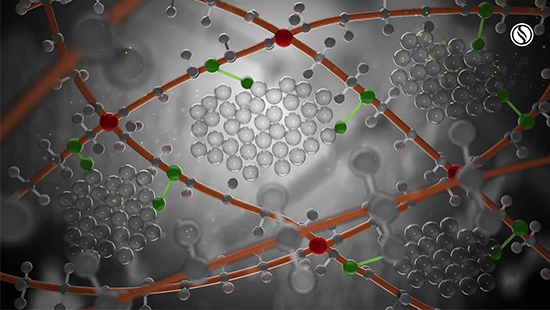

SMC Reinforced Network

Silpara’s SMCs enhance the polymer-filler interaction in natural rubber compounds, creating a nanoscale silica network in the rubber material.

This network enables key product features such as greater durability, greater efficiency due to less waste heat generation during material deformation, and greater utilization of renewable materials.

Silpara’s patented technology results in stronger polymer-filler interactions and better material performance characteristics.

Liquid-Phase Blending Technology

Using a novel process, SILPARA blends natural rubber latex and proprietary silica precursor solutions into a homogenous liquid phase blend. This blend reacts to form a true molecular composite. This is in contrast to industry standard solid phase mixing of precipitated silica particles and solid natural rubber.

This patented technology results in stronger polymer-filler interactions and better material performance characteristics.

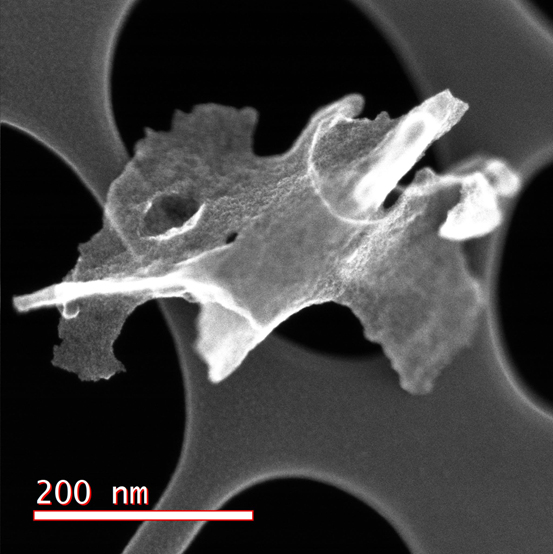

The Network in the Mix

This high resolution transmission electron microscope image shows a portion of our silica network extracted from our composite. It demonstrates the three-dimensional nature of our reinforcement network.

600 °C N2-TGA Residue SEM/STEM:

Learn More

Location

Decatur, Georgia USA

Phone

+1 (336) 392-6877

info@silparatech.com

Phone

+1 (336) 392-6877

info@silparatech.com